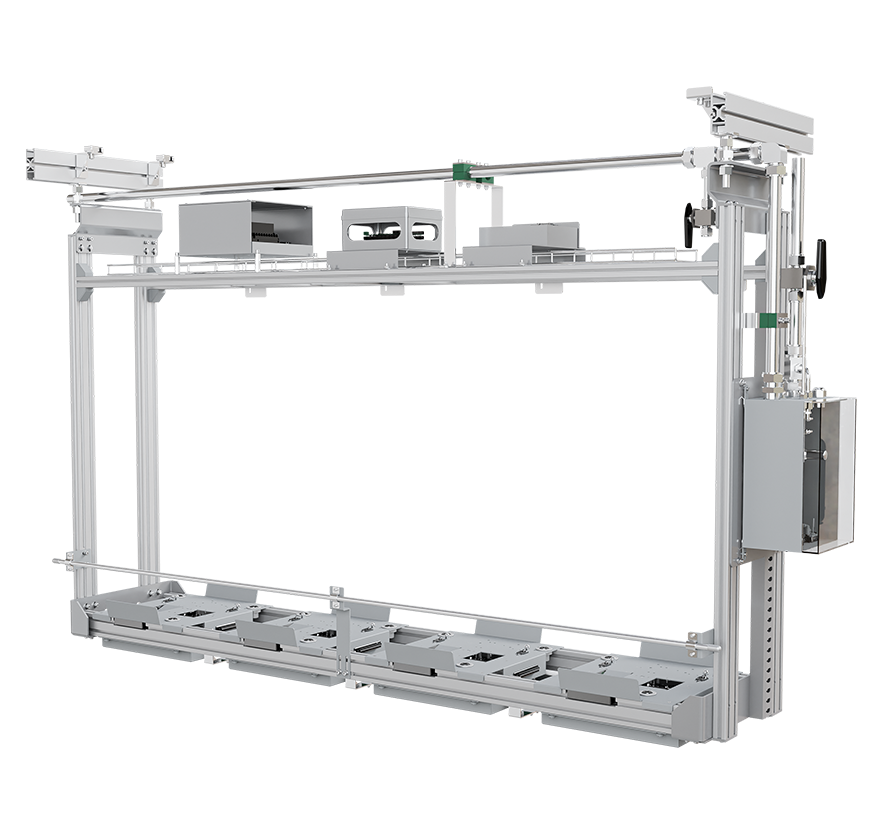

Near Tool Buffer

NTB (Near Tool Buffer) is utilized in wafer factories to connect the buffer equipment of the OHT with the loading and unloading ports of machines. This helps reduce machine waiting time and improves machine utilization.

The MeetFuture NTB is designed to be compliant with SEMI E15.1 standards and interfaces seamlessly with E15.1 compliant Load Ports.

Optional configuration: 2/3/4 Port

Optional configuration: 2/3/4 Port

Feature Highlights:

ser-friendly man-machine interface

Stable system integration

Customizable Buffer quantity

Fast moving function

SEMI S2/F47 certified

Compatibility with EAP/MCS communication

Software Description

Intelligent Buffer Control System

NTB Software

The NTB monitoring software, characterized by intelligence, high efficiency, stability, and professionalism, provides the intelligent management function for the clean room repository. It receives handling instructions issued by the client's upper system such as MCS or EAP through the HSMS standard protocol and realizes the access action of FOUP. Interfaces with standard Load Port or Sort devices via E84.

The NTB server receives tasks manually created by the upper MCS or the lower NTB user. It forwards these instructions to the PLC for execution, monitors PLC execution feedback in real-time, and reports both execution information and abnormal alarm information from the PLC. This enables automatic control of storage and delivery as well as monitoring and reporting of equipment status.

Feature Highlights:

? As an expansion port of process equipment, it can quickly dock with standard equipment to solve the problems encountered by some equipment that cannot be docked with the OHT.

? Intelligent algorithms are used to optimize the library's command execution and management logic, thereby shortening the access and handling time of wafer cassettes.

? It improves the frequency and utilization efficiency of the repository, ultimately enhancing the unit output rate of the wafer factory and creating more value for the wafer factory.

The NTB server receives tasks manually created by the upper MCS or the lower NTB user. It forwards these instructions to the PLC for execution, monitors PLC execution feedback in real-time, and reports both execution information and abnormal alarm information from the PLC. This enables automatic control of storage and delivery as well as monitoring and reporting of equipment status.

Feature Highlights:

? As an expansion port of process equipment, it can quickly dock with standard equipment to solve the problems encountered by some equipment that cannot be docked with the OHT.

? Intelligent algorithms are used to optimize the library's command execution and management logic, thereby shortening the access and handling time of wafer cassettes.

? It improves the frequency and utilization efficiency of the repository, ultimately enhancing the unit output rate of the wafer factory and creating more value for the wafer factory.

Important Parameters

| Technical Indicators | Parameters |

| Dimensions (L*W*H) | 2 Ports: 2220 (customizable)*750*2780 (customizable) |

Positioning Accuracy | ±0.5mm |

Storage Type | Foup |

Clean Grade | ≤Class100 |

| Throughput | <30s |

Vibration | <0.5g |

Noise | <75DB |

Related Product Recommendations

BACK

BACK