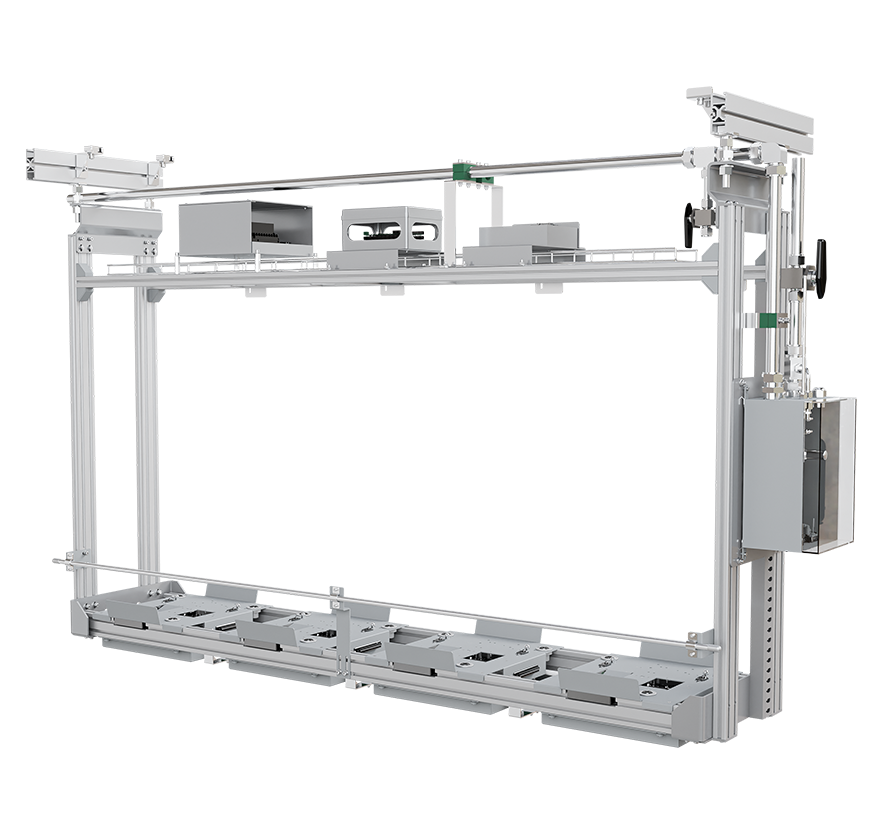

Reticle Stocker

Reticle Stocker is designed for the storage and transport of photomask pods in semiconductor clean rooms. It offers both automatic and manual docking with OHT, ensuring the quality of photomasks and ultimately enhancing the overall product yield of wafer factories. The MF Reticle Stocker is adaptable to models with hoist and without hoist.

Optional configuration: Manual Port / Number of OHT Ports / Purge Function / Auto Teaching / RFID / Wireless Power Supply

Optional configuration: Manual Port / Number of OHT Ports / Purge Function / Auto Teaching / RFID / Wireless Power Supply

Feature Highlights:

User-friendly man-machine interface

Stable system integration

SEMI-compliant pitch design

Included purge system and purge statistics function

Docking with multiple MCSs

Flexible configuration of port numbers

Integrated purge function

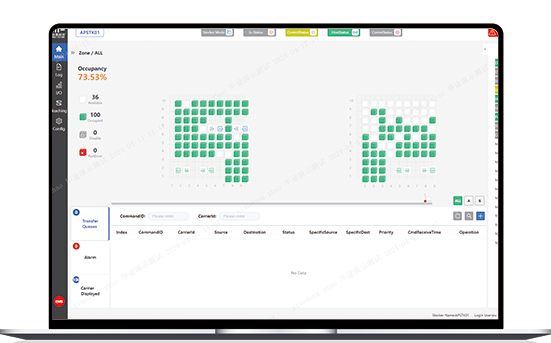

Software Description

MSSC Storage Control System

MeetFuture Smart Storage Controller

This system provides intelligent management for STK, adhering to the SEMI E88 protocol. It receives command assignments from upper-level systems like MCS to handle the warehousing and delivery of wafer cassettes. With a 3D camera, the AutoTeach function can be quickly implemented, simplifying factory installation and implementation. It also supports the reading of RFID, Smart Tag, and other tags. Equipped with self-developed RFID, SmartTag, and E84 modules, the reading success rate of this equipment reaches the industry's leading standard.

Application Scenario: Storage Equipment Control and Inventory Query

Feature Highlights:

? The MeetFuture intelligent storage control system utilizes an advanced intelligent algorithm to optimize instruction execution and materials management logic in the storage library. This results in shorter access and handling times for wafer cassettes, thereby increasing the frequency and utilization efficiency of the storage library.

? Supports docking with a variety of mainstream MCS for efficient system implementation.

? Enables real-time monitoring of multi-channel gas flow, pressure, and humidity.

Application Scenario: Storage Equipment Control and Inventory Query

Feature Highlights:

? The MeetFuture intelligent storage control system utilizes an advanced intelligent algorithm to optimize instruction execution and materials management logic in the storage library. This results in shorter access and handling times for wafer cassettes, thereby increasing the frequency and utilization efficiency of the storage library.

? Supports docking with a variety of mainstream MCS for efficient system implementation.

? Enables real-time monitoring of multi-channel gas flow, pressure, and humidity.

Important Parameters

| Technical Indicators | Parameters |

| Dimensions (L*W*H) | 8300(customizable)*1430*5350 mm (customizable) |

| Weight (full/empty) | 7.2t |

Positioning Accuracy | ±0.5mm |

| Storage Type | Reticle |

| Clean Grade | ≤Class100 |

Throughput | ≥180Lot/H |

| Vibration | <0.5g |

Noise | <75DB |

Related Product Recommendations

BACK

BACK